Support - Knowledge Base

The LVVTA Technical Team continuously compiles a database of questions and answers relating to vehicle modifications and the LVV System, to provide you with this knowledge base. This knowledge base will constantly evolve to ensure it provides the best possible source of information.

How it works

Select a category from the list, and then scroll through the topics until you find the information you're looking for.

Select a category from the list, and then scroll through the topics until you find the information you're looking for.

You can also search for specific words or phrases by clicking the 'Cntrl' and 'F' keys together (Windows) or 'command' and 'F' keys together (Mac) and typing the word or phrase into the search box.

You can also search for specific words or phrases by clicking the 'Cntrl' and 'F' keys together (Windows) or 'command' and 'F' keys together (Mac) and typing the word or phrase into the search box.

REFERENCES

The following are referenced throughout the text in this page:

BEFORE GOING FOR LVV CERTIFICATION

Back to page index | Back to top of page

What should I do before going to a Certifier?

-

Ideally, you only want to visit the LVV Certifier once, so to avoid having to book a second or third visit, do as much preparation as you can for a successful and stress-free inspection at the lowest price possible.

-

Compile a list of ALL modifications on the vehicle, not just what you think the LVV Certifier wants to know.“ALL modifications” includes modifications so obvious you think they wouldn't matter, such as alloy wheels, flares, bullbars, sidesteps, gearbox swap etc. The more detail the better; this is to help you and will save your LVV Certifier time and let them get on with the job. If the LVV Certifier misses a modification and you haven’t told them about it, this will cause delays and added costs for you in the long run. When a modification is missing off an LVV Electronic Data Plate (EDP) it will result in a WoF failure.

-

Take a copy of a WoF checksheet for the vehicle that is less than 28 days old. It pays to remedy any of the issues on the WoF sheet before you take it in.

-

Take a copy of a wheel alignment report for your LVV Certifier if you have any steering or suspension modifications.

-

Take copies of invoices for any parts you have fitted as part of your mods, so the LVV Certifier can check the manufacturer details, part numbers and the origin of the parts.

-

Take copies of invoices for any parts you have had professionally modified (driveshaft, handbrake cables, steering components etc).

-

Make sure the brakes are in excellent condition. If a brake test is required as part of the inspection, mediocre brakes will very likely fail the test.

-

Make sure all safety-related and critical function fasteners have at least 2 threads past the end of the nut and they have an anti-vibration feature incorporated positive fastener fitted (spring washers or nylocs) but don’t fit nylocs to hot components (i.e. brakes and exhaust) - use a spring washer or another suitable method.

-

Make sure the vehicle is relatively clean and tidy and there is sufficient fuel for a brake/road test (which in some parts of NZ, especially in congested cities, can take over an hour)

-

How long does it take to get a vehicle certified?

-

-

This depends on the LVV Certifier - if they are busy it can be several weeks until they can fit your appointment in. Make sure you ask the LVV Certifier how long they will need the vehicle for; you may need to leave the vehicle there for a day or two, or longer for an extensively modified, or scratch-built vehicle.

-

Your LVV Certifier may require some disassembly of the vehicle to enable proper inspection. In some cases, you may need to discuss who you want to do that work.

-

Once the inspection has been completed you will be given a list of rectifications (unless it passes first time).

-

How long it takes to complete the rectifications is up to you but should be done within two months of the initial inspection or a full re-inspection will be required. If you are going to take more than two months check with your LVV Certifier first and keep in touch with them regularly to let them know how you are going or if you have any questions.

-

After completing the rectifications, they will need to be rechecked, and providing everything is found to comply, the LVV Certifier will complete and compile the paperwork and photographs (which can take a while) before they send the application to LVVTA for processing.

-

The LVV Certifier may not send the application to LVVTA for processing until you have made full payment.

-

When the application arrives at LVVTA it will be processed by our plating and technical staff, who will ensure all applicable requirements have been applied, and load the details of your certification into the LVVTA Lookup system.

-

Finally, the EDP is activated and the LVV Certifier advised.

-

LVVTA have a target three-day turnaround to process the EDP from receipt of the paperwork. Providing no issues are identified during processing, LVVTA meet this target 90% of the time and often have same day turnaround. It may take another day for the EDP LVV certification data to be made live on the LVVTA Lookup system.

ATTACHMENT Systems

(Fasteners, welding, adhesives etc)

Back to page index | Back to top of page

Some of the most common mistakes made when modifying your vehicl are as follows:

1) Not having enough threads protruding past the end of a nut on a fastening used in a safety-related application. The threaded section of a fastener used in a safety-related application must protrude through the outer end of the nut to which it attaches by at least two full threads.

2) Welding a casting or forging before reading the requirements. A basic, but very important engineering principle threaded throughout the whole LVV certification process in NZ is that a forging or casting in a critical situation like suspension, steering, or brakes, must not be heated and bent, or welded, except in highly controlled circumstances.

3) Fitting ‘nylocs’ in high-temperature areas or using them more than once. A ‘nyloc’ nut must not be used to secure a fastener in a low volume vehicle, where there are extremely high temperatures within the immediate vicinity or in the case of attachment of safety-related components or systems, be attached to a fastener in a low volume vehicle repeatedly.

4) Using ‘Loctite’ instead of a spring washer, split pin or other thread locking device. Fasteners used in a safety-related application within a low volume vehicle must be secured with a ‘nyloc’ nut, spring washer, split-pin, or other vibration-proof locking device. Loctite’ or other thread adhesives are not an approved vibration-proof locking device for the purpose of LVV certification.

Where can I get a copy of the F008 Non-destructive Test Request Form?

The F008 form is available from your LVV Certifier and needs to have some sections completed by them to ensure correct information is supplied to the NDT inspector, to ensure the relevant testing can be carried out.

Can I weld to a cast or forged component?

Generally, no you can’t. However, there is a pathway for those who wish to go through the correct process. There are a number of things to consider when welding to a casting or forging, as a lack of correct welding procedures or poor welding practices can introduce dangerous and sometimes unseen defects into the component making it more likely to fail.

If you just plan on welding to a casting or forging without the right information, tools or process please don’t; it will not pass LVV certification, and you will have wasted your time and money.

If you would like to find out material specifications, develop a welding procedure and carry out a strong, safe modification then this can be done. All the information you require can be found in LVV Info-sheet #01–2018 (Welding Process for Cast or Forged Steel Components)

Back to page index | Back to top of page

What is an LVV Authority Card?

A card specifying alternative safety related equipment for a specific person and vehicle.

LVV Authority Cards cover fenderless vehicles (for example hot rods), and occupant protection systems (for example motorsport vehicles).

Three organisations currently issue authority cards:

- NZHRA – example; fender exemptions for hotrods

- Motorsport NZ – example; race seats, harness seatbelts, roll cage, SRS airbag removal).

- NZ Drag Racing Association; example - harness seatbelts, roll cage.

- IHRA NZ

- example; harness seatbelts, roll cage.

For more information, please refer to Chapter 3 of the NZ Car Construction Manual, or section 2.12 of the LVV Code.

Body

Back to page index | Back to top of page

I want to do a body drop on my ute and want to do it by just cutting the floor either side of the chassis rails and welding a U shape section in place to allow the cab to sit down over the chassis, also doing the same over the cab mounts. Because all the seat/seatbelt mounts etc are unmodified and the cab mounts themselves are all still the same does it need to be certified? Being a cab/chassis rather than a unibody vehicle does that make a difference?

If you’re dropping the body over the cab (this is commonly referred to as channelling), you’ll definitely need LVV certification. Although the mounts themselves might not be modified, the load paths (including all seatbelt loads) will now travel through your modified floor and the attachment to the rest of the body structure. You’ll also have to modify the steering column which will also require LVV certification.

I want to do a body lift on my 4WD, what do I need to do, does it need certification?

Yes, all body lifts require LVV certification. You will need to ensure the lift blocks themselves are of a suitable size, design and number. In practice this means you need at least the same number as the manufacturer originally provided; each block must be at least the same diameter as the OE mounts, and the blocks must be made of a suitable non-compressible material. The longer fasteners holding everything together will still need to meet the LVV minimum requirements as set out in NZCCM Chapter 18 (Attachment Systems). When lifting a body, you will also need to consider other systems such as steering, brakes, handling and SRT (static rollover thresholds). We would recommend talking to your LVV Certifier before starting.

Are carbon fibre or fibreglass panels allowed for exterior panels without getting a cert, including - bonnet, boot, fenders, doors, grille and bumpers?

Yes, this is allowed so long as they meet a few requirements. If the vehicle is required to comply with a frontal impact protection standard:

-

no frontal impact-related components can be removed; and

- the panels being removed must not contribute to the vehicle structure, including its side-impact resistance; and

-

the panels must use the OE attachment points; and

- the kit or components must not present any external projections that could cause injury or present a snagging/hooking risk.

Note that if the vehicle’s OE guards are spot-welded onto (or otherwise form part of) the vehicle’s frontal structure (such as Mk1/Mk2 Escorts), fitting a fibreglass or composite guard means the vehicle will need LVV certification by a category 1D LVV Certifier, because the frontal structure has been changed.

Can Lambo or scissor doors be certified?

Yes, provided the new door hinges and door latches all meet applicable requirements and the structure supporting the doors is adequate. This modification requires LVV certification and may also require some additional engineering analysis to validate the strength of the assembly.

Can I remove the roof of my HQ Holden and make it a roadster?

In principle yes, it can probably be done. However, what you have to do (in a nutshell) is replace the structural strength and integrity lost by the removal of the roof, with some other means of stiffening up the car's structure again. In older separate body/chassis cars (like Chevy Impalas for example) this was much easier, but modern unitary constructed cars rely on the roof of the vehicle to keep the whole vehicle from collapsing in a heap and contribute to the vehicles crash performance.

There are different ways of doing this; a roll-cage structure is one way, closing the doors up (structurally) to form a 'tub' is another, or strengthening the floor-pan by incorporating a perimeter chassis is the best way but probably the most expensive (and difficult). You'll need to contact a local category 1C or 1D LVV Certifier before you start to make sure that what you’re planning will be acceptable. The LVV Certifier will be able to assist you in designing and fitting the additional strength required to ensure the vehicle structure can handle the loads imposed by the doors, seatbelts, drive-train, brakes, and everything else. You'll need to remember to incorporate a rollbar (or other suitable structure) in order to reattach the upper seatbelt anchorages if the removal of the roof means no structure in the 'permitted area'. If you are thinking of future motorsport events you should incorporate a rollbar that complies with MANZ or NZDRA specifications.

Can I fit a sunroof or vent/hatch to my vehicle without certification?

Yes, provided that the fitting has not weakened the vehicle structure. Heating, drilling, welding or cutting the vehicle structure, modifying a roof bow or any part of the structure, would be considered to weaken it. Cutting a single layer of unstressed panel of sheet metal (i.e. roof) is not considered to weaken the vehicle structure.

Roof chop: Can I cut an inch or two out of the roof of my Nissan Silvia S14?

No problem on something a bit older like a Silvia and it would be interesting to see how the roof-chops on a more modern vehicle would look. As always, with any significant or unusual modification it’s always advisable to contact your LVV Certifier before getting started.

As time goes on and manufacturers look to meet changing regulations and trends, the techniques and materials used in building vehicles are also constantly evolving, so what used to be acceptable on an old Chevy or Ford, might not be OK on your Silvia. The common use of ultra-high strength steel in modern vehicle pillars, and complex frontal impact systems means that each vehicle would need to be considered on its own merits, and there will be vehicles where a roof chop is not possible.

How legal do you think it would be to have a fully chromed car? I have seen some pics of this done in Europe and it looks pretty cool. I know mirror tints are illegal, so I'm guessing a car that was fully mirrored out in chrome would be a no-go too?

NZTA has confirmed that there’s no rule that prevents a body from being chrome wrapped (or plated), although there is a rule that glazing (glass) cannot have a mirrored finish. This doesn’t mean that on-road enforcement won’t see it differently, perhaps determining that it may cause a distraction. One defence to this, besides pointing out that there’s nothing that makes it illegal, would be that some trucks and trailers have stainless steel polished panels which would be as bad (if not worse), at reflecting light and causing a hazard in certain conditions.

Is it ok to have a tow hook at the back of the car that protrudes out from the bumper about 10cm? My exhaust pipe sticks out the back of the car about 5cms, as they have to exit out from the car, so what's the difference?

There is no defined amount specified in the regulations for bits sticking out the front or back. The relevant piece of legislation (VIRM, 2.1 (External projections)) says that a protruding object or fitting that has a functional purpose must be installed so the risk of the object or fitting causing injury to a person is minimised. Without seeing a picture it's hard to say, but my guess is that your tow hook would not be in breach of that requirement and no worse than a towbar.

Shaved door handles – do they need a cert?

Yes. The only available under threshold modifications to exterior door handles are minor (e.g. removal of key locks), and the door handles must remain fitted and in serviceable condition. LVV Standard 155-20 (Door Retention), Section 2.6 allows for shaved exterior door handles and sets out the requirements that must be met for LVV Certification.

The main thrust of these regulations is that the doors must be able to be opened from the inside by mechanical means (no electrics), and only external opening of the doors can be done electrically. However, although doors can be unlocked by remote, they shouldn't be unlatched by remote. This is due to the risk of doors being opened when you don't want them to while travelling, by interference from some other source like a microwave speed detector (Police ‘radar gun’). There is at least one American kit that does enable remote unlatching without safety risks, by cutting out the ability for the system to operate when the ignition is on, or the vehicle is in gear.

I’m putting a bed in the back of my Toyota Estima so I can go camping. It’s not self-contained, does this need certification?

Self-containment certification is not the same as LVV (or modification) certification. You would need to speak to the NZ Motor Caravan Association or your local council.

On this type of vehicle, typical items that would need LVV certification include a pop-top or high-roof conversion and cutting any holes in the body that affect the structure (e.g. for gas bottle access).

Can you remove a bonnet from a vehicle and get it certified?

According to the NZCCM Chapter 9 (Engine & Drive-train), paragraph 9.6.3:

“Unless authorised by an LVV Authority Card specified under Annex 5 of the Low Volume Vehicle Code, a low volume vehicle must be fitted with a functional engine hood so as to minimise the likelihood of additional injury to pedestrians through contact with engine components.”

Basically, if the vehicle has had modifications that are covered by NZCCM Chapter 9(Engine & Drive-train), it must have a bonnet - unless it is eligible for an LVV Authority Card, and the owner wishes to remove it.

A vehicle not covered by NZCCM Chapter 9 (Engine & Drive-train) must still meet General Safety Requirements, which means any modifications must not reduce the safety of the vehicle below a safe tolerance of OE. Removal of the bonnet would likely drop the vehicle below the specified OE safety tolerance - so the bonnet must remain. A clear bonnet (polycarbonate or clear resin) could be an option.

GT-style rear wings (spoilers) – How big can they be? I have one that is constructed from carbon fibre (the blade part) and aluminium (the stays) and is secured by bolts that go right through my boot. The wing doesn't extend out wider than the car but is about 50cm high off the boot itself.

Provided it is a professionally manufactured item, securely attached, and the outer ends of the wing do not extend beyond the widest part of the body (not including the mirrors), you should be ok, but it will always come down to an inspection to confirm. You will also need to consider your rear lights, depending on the size and position of the stays, and the spoiler itself - you may be partially obscuring a light (the performance of any lamp must not be affected as a result of fitting the kit or components).

I’ve put an air mattress and some cupboards in the back of my Nissan Vanette to make it into a campervan. According to your threshold document, because it’s had a camper conversion this means it needs certification?

The intention of the LVV Certification Threshold Schedule is that vehicles which have undergone a cab-cut or had other structural modifications in order to become a campervan require LVV certification. Generally speaking, as long as no cutting/heating/drilling/welding of any structural part of the vehicle has taken place because of the camper conversion, no seatbelt anchorages have been modified or added, or any other above-threshold modifications have taken place, this would not require LVV certification.

Brakes

Back to page index | Back to top of page

Cardan shaft handbrakes – are they legal?

A Cardan shaft handbrake can be used, provided the vehicle is fitted with a dual-circuit master cylinder. This is detailed in the NZCCM Chapter 8 (Braking Systems), paragraph 8.9.4.

Can I install a push button handbrake?

Yes, you can. These are already reasonably common in vehicles adapted for disabled drivers, and provided it’s of adequate quality the certifier should have no problem approving it. This modification is covered in the Braking System chapter of the NZ Car Construction Manual.

Do brake upgrade kits require LVV certification?

Yes, if the brake calipers are changed from OEM, or the disc is not a direct replacement (i.e. the same size) for OEM, your vehicle will require LVV certification. OEM refers to the components that were fitted to the vehicle before it left the factory - this means that a Commodore SS fitted with HSV GTS brakes must be LVV certified. Both are Holdens but the SS left the factory with different brakes to the GTS and there may be other differences between the brake systems that could affect performance, such as front-rear bias.

Do stainless steel brake hoses and fittings need to be LVV certified?

Stainless brake fittings and braided hoses don’t require LVV certification provided they meet the requirements found in the VIRM, In-service certification, General vehicles (Brakes/Service brake and parking brakes) Section 8.1, Tables and images. In terms of meeting WoF standards though, the fittings would need to be direct replacements installed using all OE attachment points, and the hose end must be permanently attached to the end fitting, such as by crimping. Refer to LVV Info-sheet #04-2007 (Stainless Steel Braided Brake Hoses).

Can I have a hydraulic handbrake certified for road use?

No - you can’t have a hydraulic handbrake fitted unless it is covered by a valid LVVTA-approved Authority Card. Refer to MotorSport NZ's website for further information.

Brake upgrade on a 94 Mivec Mirage: The car has the same brake setup as a GSR Lancer - however, my PCD is 4x100 (instead of 4 x 114). I plan to use a DBA slotted rotor from an early EVO and either an EVO or Wilwood caliper.

- Can I re-drill the rotors to suit a 4 X 100 PCD?

-

The EVO rotor is 20mm bigger and all the other measurements are the same i.e thickness, height etc. except the centre hole on the EVO rotor is 69mm versus my current rotors 64mm - this will bolt up fine, but will it get a cert?

- Can I weld a bracket to mount an aftermarket caliper?”

Might be OK, might not be. There are two rules of thumb that kick in here. Firstly, never weld up the holes from one set of studs in a casting or forging (which a hub is, in nearly all cases), and secondly don't re-pitch a 4-stud hub to a 5-stud or any other odd combination where the holes come too close or overlap. Going 4 onto 4 which you want to do is usually OK, especially if the PCD's are only slightly different, because there's tons of room for you to simply re-drill your new PCD in between the old one. Having said that, it will not work in a situation where the rotor is a separate item to the hub because the area between the wheel studs is generally used to attach the rotor to the hub. Make sure you use someone who really knows what they're doing though - if you don't know anyone suitable, ask your LVV Certifier.

In a perfect world, every wheel would locate snugly over the hub centre spigot, so the hub is supporting the weight of the wheel, and the wheel nuts or bolts are only clamping the wheel against the hub. In reality there are probably dozens if not hundreds of fitments every day where this doesn't happen, so the wheel nuts or bolts both clamp and support the weight of the wheel, but provided everything else is right, history tells us it shouldn't be a problem, and can be LVV certified. LVVTA certainly recommends having that spigot support, and reputable wheel manufacturers provide spacer rings that fill lots of common gap sizes so this can be achieved.

Re the caliper bracket, it depends if you're talking about welding two or more pieces of a fabricated caliper bracket or welding a caliper bracket to the suspension hub or stub axle. If it's the former, it can be done, but you'll need to use a seriously specialised, competent, and reputable expert, with NDT (crack-testing and weld inspection) carried out afterwards. If it's the latter, welding to a hub or stub axle is an absolutely no-way, no-can-do, forget-it scenario, because of the problems associated with welding a forging or a casting.

Brake upgrade with power increase or engine conversion: Is there a point where brakes must be upgraded, or does it just come down to them being tested when I go for the cert?

There isn't a cut-off point where bigger brakes must be fitted, the determination as to whether your brakes are suitable for their new job is made by the LVV Certifier as part of the inspection process. Your vehicle will need to pass the brake tests as set out in the LVV Standard 35-00(02) (Braking Systems). For vehicles with an increase of more than 20%, this will involve the LVV Certifier carrying out a cyclic brake fade resistance test of three or five stops from 100kph within a given time to check if your brakes can cope with the increased performance. An increase in power or torque of between 20% and 50% will require a three-stop test, while an increase in power or torque of more than 50% will require a five-stop test.

As you can imagine the number of potential vehicles/conversions is almost infinite, adding the fact that some cars leave the factory with decidedly average brakes whilst other cars have awesome braking systems, it becomes impossible to set a point at which an upgrade needs to occur. What you can be sure of, is that worn out, poorly maintained, or cheap components are not going to help your cause, so do consider refreshing the brakes and maybe using some decent performance pads.

A final word of caution here, don't go too wild on the pads though - the pads that serious race cars use usually require a lot of heat to build up to a point where they work properly. Some pads will need one or two hard-out laps around Pukekohe before they're fully in business and are not suitable for road-going performance cars - they can be dangerous.

Chassis

Back to page index | Back to top of page

I’m looking at importing a pick-up that’s got a bolt-in C-notch fitted. Will this pass cert?

We’ve seen quite a few vehicles come through with these, and there are plenty that don’t restore the full strength of the original chassis rail. While you may never intend to have a load on the tray and only use the vehicle for cruising or attending shows, the next owner may fit a tow bar and/or load up the vehicle with tools etc, putting much higher loads on the rear end of the chassis, which could lead to a bent chassis… not ideal, and certainly not something an LVV Certifier would be willing to put their name to.

If you’re importing a C-notched vehicle or are planning on fitting one, consider the requirements in the NZCCM Chapter 5 (Chassis Modification & Construction), paragraph 5.3.2:

“The area of the chassis at and adjacent to a C-notch must be suitably reinforced in order to reinstate the strength and rigidity lost in that area of the chassis as a result of the modification”.

Be aware that a bolt in C-notch will very likely need to be replaced by a more suitable, fully welded item or have additional strength added.

I would like to C-notch my car but I’m unsure of the steps I need to take. Do I do my C-notch then take it to the Certifier in a finished state or do I have to apply for an LVV certification before I start?

It is advisable to contact an LVV Certifier early so they can do a progress inspection and offer advice on the right method for the modifications. It is a major structural change so needs to be done correctly (the LVV Certifier will still need to see the finished vehicle to be able to certify it). NZCCM Chapter 5 (Chassis Modification & Construction), section 5.3 has information on this type of chassis modification.

I’ve got an old project that has live plates (rego on hold). I’m looking at putting a chassis from a different manufacturer under it. From what I’ve read, if I swap the chassis, it will become scratch-built? If this is so, how will this affect my plates? Or will I need to keep 60% of the factory chassis rails to keep it classed as a modified vehicle to keep my plates?

You’re right, fitting a chassis from a different production vehicle manufacturer onto your vehicle will make it scratch-built. You’ll then need to meet some extra requirements that may not apply to your vehicle now, for example: burst-proof door locks, collapsible steering system, and if it’s currently left-hand drive you’ll need to convert it to right-hand drive. All scratch-built vehicles are registered as ‘new’ vehicles so you would not be able to transfer the original vehicle’s identifiers, tags or registration plates in this situation. To remain as a modified production vehicle, there are some situations where a replacement chassis can be used - more information can be found here: LVV Info-sheet #02-2018 (Modified Production & Scratch-built Low Volume Vehicle Definitions).

Can a complete 3x2 RHS chassis be chromed?

Yes, providing the entire chassis is mild steel (not high tensile steel) and the weld is also low tensile material. Chroming high tensile steels can introduce hydrogen embrittlement and is applicable across any component made of high tensile steel used on a Low Volume Vehicle, including components such as axles, springs, stub axles and fasteners. Tiny cracks can appear at the points where hydrogen embrittlement has occurred, particularly after continued movement and loading, eventually leading to the failure of the component. Also, bear in mind that a component should never be electroplated more than once, as the hydrogen embrittlement that is likely to occur during the process is cumulative.

-

DISABILITY

Back to page index | Back to top of page

I’m looking at importing a disability van from overseas. If it’s been on the road in another country, do I need to get a cert?

It depends on the modifications. Once the vehicle enters New Zealand, it will need to go through an ‘Entry Compliance’ inspection. If the inspector identifies a modification that is over-threshold and needs LVV certification then yes, you will need to get the vehicle LVV certified. You would be amazed at just how unsafe many vehicles are on the road overseas. There are other things to look out for as well; a vehicle sourced from the UK for example may be rusty or poorly modified while others have non-compliant wheelchair restraints or systems which will require replacement.

There are some vehicles offered directly from the vehicle manufacturer (Toyota for example), sold specifically as disability vehicles. Unless the vehicle is Euro type-approved or a Japanese vehicle with TDN they will all still require LVV certification. Please contact an Entry Compliance Centre, or the LVVTA office if you have any questions.

Do wheelchair anchorages need LVV certification?

Yes, wheelchair anchorages always require LVV certification.

Do wheelchair hoists require LVV certification?

Yes, all wheelchair hoists require LVV certification (unless it’s a hoist for stowing or deploying an empty non-powered wheelchair from the luggage area). See the LVV Certification Threshold Schedule for details on a range of disability modifications.

ELECTRONIC DATA PLATES (EDP)

Back to page index | Back to top of page

I’ve just had the final cert inspection on my car, and I scanned the electronic tag and nothing comes up. What’s going on?

The EDP is not immediately live when it is attached to the vehicle. Vehicle information and photos will be added to the LVVTA database once all LVV certification documents have been processed at LVVTA head office. Our target turnaround time is three working days after the paperwork arrives at LVVTA, although this can be a week or two after the final vehicle inspection as the LVV Certifier needs to complete their paperwork before submitting it to us in Wellington. The LVV Certifier involved will be notified once the EDP has been activated. If the EDP hasn’t been activated within three weeks of the final inspection, contact the LVV Certifier.

Can I remove the EDP to paint the car? Can I just paint over the EDP?

We wouldn't recommend painting over an EDP if for no other reason than you then couldn’t see the numbers printed on it to use the online lookup feature.

Note that if you want to remove the EDP prior to painting, you’ll need to see an LVV Certifier to remove and re-attach the plate.

Can I take the orange sticker off and just have the EDP?

Yes, but you can't remove the EDP to do so. This isn’t recommended because the orange sticker is there to identify the EDP.

What happens if my adjustables wear out and I need to replace them? Do I need a recert because they won’t match the photos?

If the coil-overs are the same brand and type (for example if you replace your TEIN coil-overs with replacement TEIN coil-overs with the same part number, and have the same springs fitted), the replacements would be considered a repair. However, if different a brand or type of coilovers are used, they may have different adjustments, settings, springs, shock-rates, platforms, and other specifications and aspects may differ. These would need to be recertified.

What happens if I’m pulled over and the cop can’t look up the EDP photos?

In the event that you are pulled over in an area with no cell coverage, the officer will direct you to a location with cell coverage.

ENGRAVED CERTIFICATION PLATES (ECP)

Back to page index | Back to top of page

My certification plate has had an error or omission since the vehicle was certified, how do I get it corrected?

The process to correct an LVV certification plate error is to contact LVVTA on info@lvvta.org.nz to advise us of the error or omission and we will recall of the certification paperwork from off-site storage. This will cost you $50 (it takes a few days for the paperwork to get back to us). If we find the plate production sheet shows LVVTA were responsible for the plate being recorded incorrectly, we will refund the $50. If not, then we can look through the paperwork to see if there is any evidence of the modifications being present and assessed at the time of certification to give us reasonable grounds to agree to a plate correction.

If we can establish that there are suitable grounds for a plate correction, an LVV certifier will be required to inspect the vehicle to ensure the rest of the vehicle still matches the current certification plate. If there are any new modifications, then the vehicle will need to be recertified, if there are only removed modifications it will require a partial return to standard process. But if the vehicle matches the certification plate other than the error or omission, then the certifier will contact us requesting a plate correction and confirm the vehicle matches the plate, LVVTA will update the EDP or engrave a new plate and send it to the certifier to fit when they remove the old plate.

If there is no evidence of the modifications being present or assessed at the time of certification, then the vehicle will need to be re-certified for the uncertified modifications, but we do try our best to find the information in the paperwork where there are suitable grounds to believe there was an error.

There are abbreviations on my engraved certification plate - what do they mean?

It can be difficult, if not impossible to fit full descriptions of all the modifications on a certification plate. Therefore, it is often necessary for us to abbreviate some modifications. Click here for a list of commonly used abbreviations that you may find on your LVV certification plate. If you can’t find what you’re looking for on the list, feel free to email info@lvvta.org.nz and we can hopefully help solve the mystery.

Engine & Drive-train

NZ Car Construcrtion Manual - Chapter 9 - Engine & Drive-train

Back to page index | Back to top of page

Why do modified wastegates need to be certified?

A wastegate controls the boost pressure by controlling the exhaust gas flowing over the turbine, allowing some gas to bypass the turbine which slows it down causing less air to be forced into the engine. Therefore, the wastegate is an easy and cheap method of increasing horsepower, potentially by a considerable amount.

The VIRM, In-service certification, General vehicles (Miscellaneous items/Engine and transmission) Section 13-1 Tables and images lists minor modifications that are allowed to an engine under threshold as well as modifications that are not minor and therefore over threshold. “Upgrading/modifying the wastegate” is listed as a modification that is not minor and always requires LVV certification.

The VIRM, In-service certification, General vehicles (Exhaust/Exhaust system), Section 11-1, Reasons for rejection, Note 6 also states:

“Externally venting wastegates (screamer pipes) are not permitted and cannot be certified as they are not adequately muffled and the exhaust gasses do not exit behind the passenger compartment. However, wastegates that feed gasses into their own muffled exhaust system exiting behind the passenger compartment, or feed gasses back into the vehicle’s exhaust system, are permitted”

LVV certification is still required if the wastegate is upgraded or modified.

Does an auto to manual gearbox conversion require certification?

In most cases it will because of the changes needed to complete the conversion. One area that many forget about is the brakes; the braking system must not be modified or changed, including the brake pedal and pedal-box assembly. The full requirements can be found in the VIRM, In-service certification, General vehicles (Miscellaneous items Engine and transmission) Section 13-1.

I have done a custom engine conversion and there is no physical room for a front-engine mount due to the exhaust downpipe and top mount manifold location. Do I need a front engine mount for certification?

In a front-drive engine, this mount would be needed to control the torque of the engine. It may be possible to do without this mount but there would need to be enough torque control in the remaining engine mounts to handle this on their own without overloading of them or their attachment points. We suggest you discuss your particular requirements with your LVV Certifier or with a modifier who has had a similar modification LVV certified in the past – in a situation like this, there is no substitute for being able to see the vehicle and figure out the best solution.

Do I need to fit a catalytic converter to a VS Commodore with an LS conversion?

It depends on a number of things, principally when the vehicle was manufactured, the date of first registration in New Zealand, and when the engine was first available. The VS was manufactured between 1995 and 1997, and the LS1 was first seen in a Holden from 1999 in the VT Series 2 Commodore. In this case, the vehicle would not need a catalytic converter; however, each situation needs to be considered on its own merits.

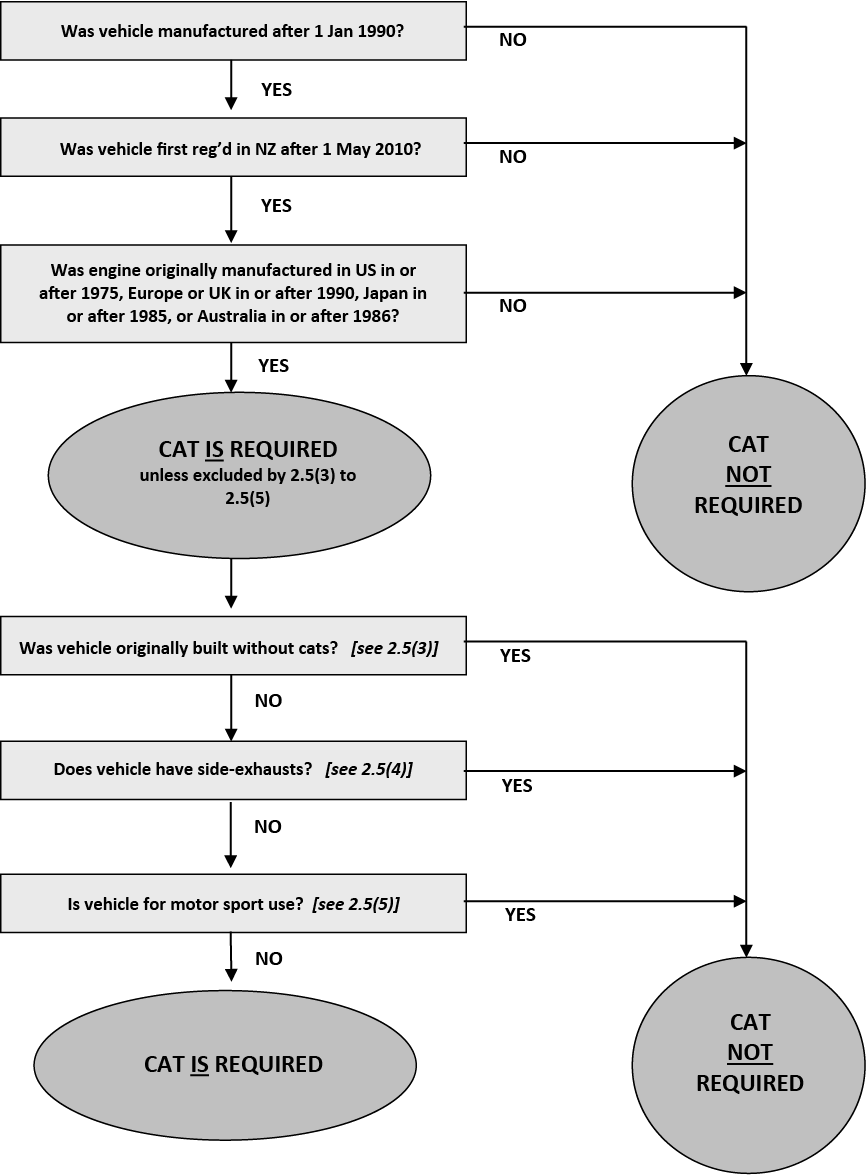

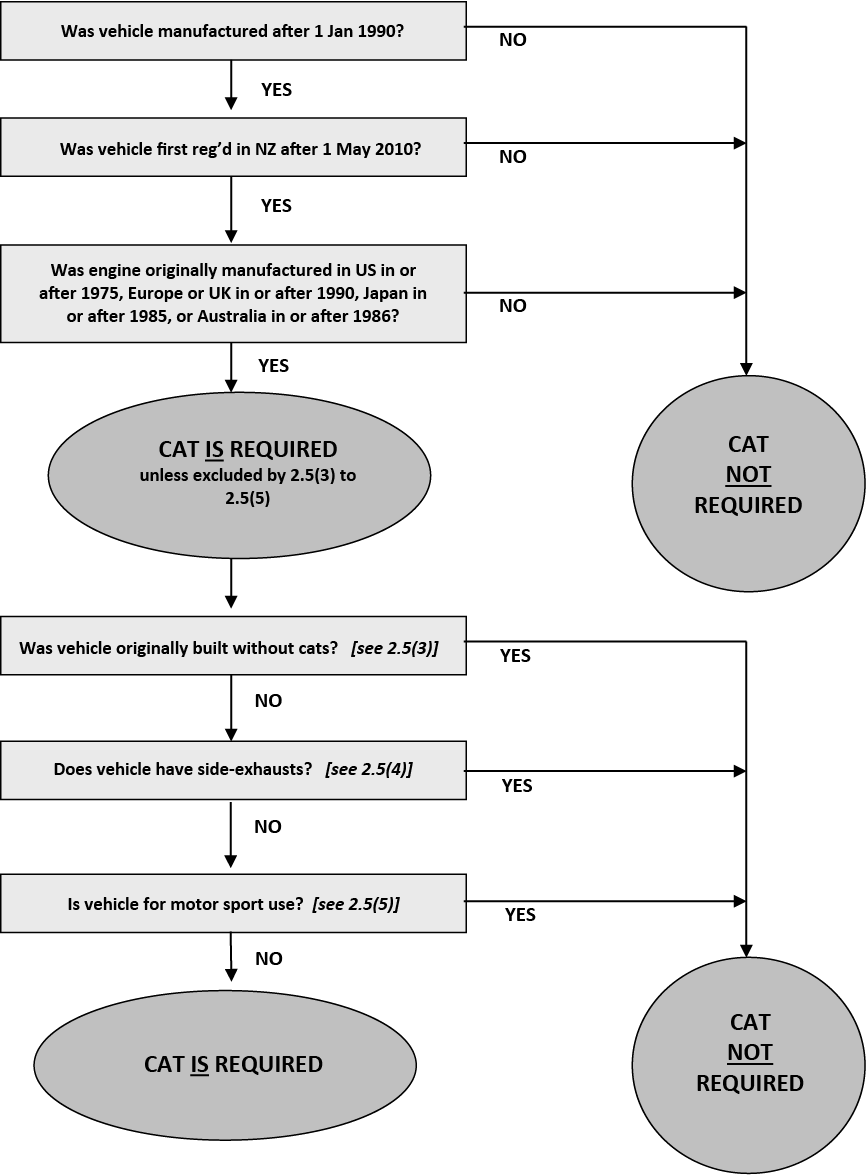

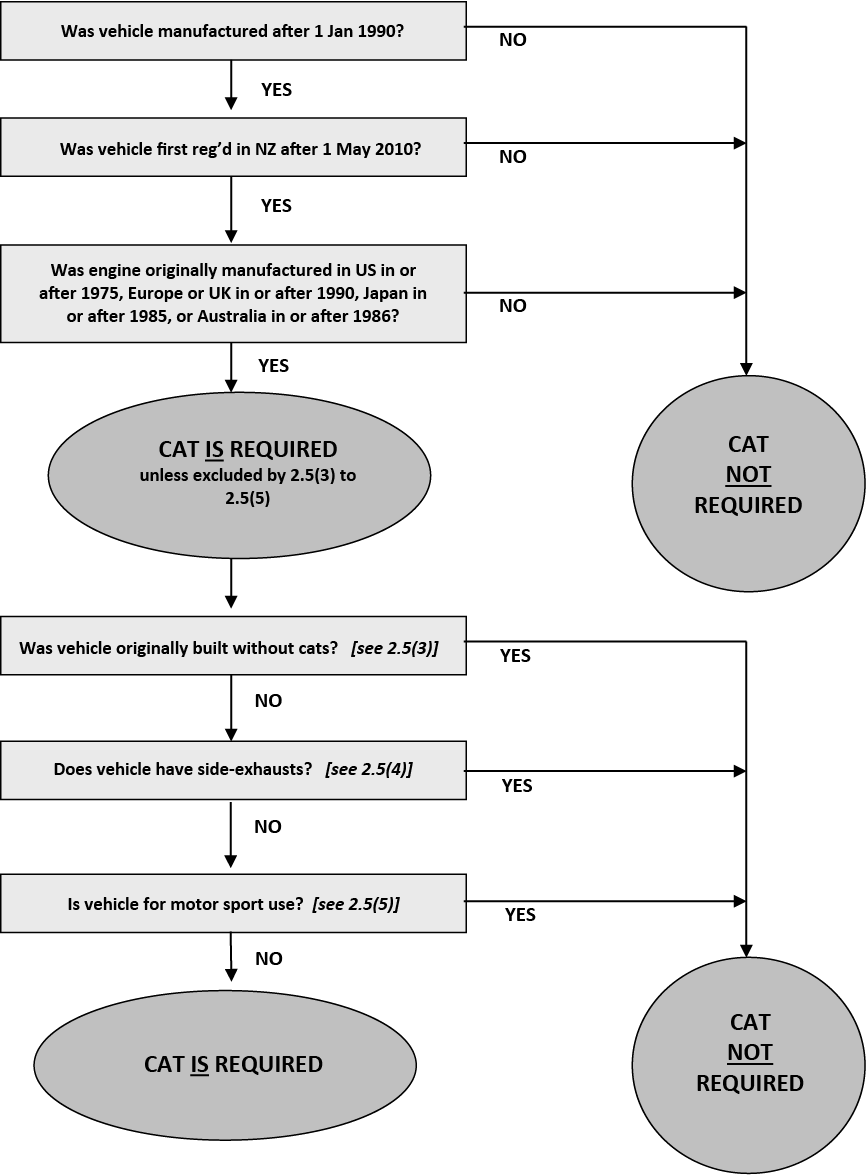

The flowchart below is taken from the LVV Standard 90-10(03) (Exhaust Gas Emissions) and can be used as a guide when deciding if your vehicle needs one fitted.

Click to enlarge

What are the rules around gearbox cross member modification? I’ve put a different gearbox into my car and the old cross member doesn’t fit anymore. Do I have to get a complete new cross member fabricated or can I just have the current one modified? Also, what material and thickness am I allowed to use? And does it matter if it’s TIG or MIG welded?

Yes, you can modify your existing cross member. The material size will depend on the extent of the modification, but the strength should be no less than that of the original cross member. Both TIG and MIG are OK, and modifiers can carry out their own chassis and other non-critical component welding even if they are not formally qualified, providing they can satisfy their LVV Certifier by way of a practical assessment, that they are competent in the particular type of welding being used. This test has been developed specifically to enable competent people to carry out their own structural welding if they so desire, without needing a formal welding qualification.

When does a driveshaft safety-loop need to be fitted to a low volume vehicle?

According to NZCCM Chapter 9 (Engine & Drive-train), paragraph 9.22.1, a driveshaft safety-loop must be fitted around the forward end of each section of driveshaft on any low volume vehicle of a front-engine and rear-wheel-drive configuration, a 4WD configuration, or an AWD configuration, and which incorporates an open drive-line, if:

-

the vehicle has had an engine conversion that has resulted in a significant (more than 50%) increase in power or torque; or

-

the vehicle’s factory-fitted engine has been modified, such that a significant (more than 50%) increase in power or torque has resulted; or

-

the driveshaft fitted to the vehicle is aftermarket including steel, carbon-fibre, aluminium or composite, or where the driveshaft has been modified by welding.

Provided that all driveshaft components are identical between the variants of the vehicle, the above requirements do not apply where either:

-

a same make and model variant engine conversion has occurred; or

-

a same make and model variant turbocharger or supercharger conversion has occurred.

Also, the requirements outlined in NZCCM Chapter 9 (Engine & Drivetrain), clause 9.22.1 do not apply where:

-

a driveshaft hanger bearing is positioned directly behind a driveshaft universal, and the hanger bearing is designed in such a way that it will effectively contain a failed or disengaged driveshaft; or

-

a chassis or sub-frame member or section is positioned in such a way that it meets or exceeds the requirements for a driveshaft safety-loop.

The front driveshaft in a 4WD vehicle is not required to have a driveshaft safety loop unless (unusually), a front driveshaft is able to make contact with the road surface or critical mechanical components. In such cases, vehicles should be dealt with by the LVV Certifier on a case-by-case basis.

For more information, please refer to NZCCM Chapter 9 (Engine & Drivetrain).

-

Will my vehicle require LVV certification if I increase the engine size?

Yes. The VIRM, In-service certification, General vehicles (Miscellaneous items Engine and transmission), Section 13.1 states that LVV certification is required if an engine being fitted to a vehicle is not of equal or lesser cubic capacity than the one being replaced.

The VIRM classifies an engine capacity increase as a modification if it exceeds usual reconditioning – for example, overboring your tired 302 Windsor by .020” would be considered a minor modification as part of normal reconditioning, but stroking it out to 347ci isn’t a minor modification, and would thus require LVV certification.

Will I require LVV certification if I increase the power of my engine?

It depends on how much of an increase there is. The VIRM In-service certification (Miscellaneous items Engine and transmission), Section 13.1 states that LVV certification will be required if the increase in power and/or torque is more than 20% over the OE engine. Adding a supercharger or turbocharger automatically requires LVV certification.

I am converting my Honda Integra to RWD with the help of a Honda S2000 engine, gearbox and driveline. Should I enlist the help of an LVV Certifier for advice before I turn a spanner (and gas axe!) in anger? I have heard that I should take pictures as I go to show the Certifier, but of course, by then it would be too late, as it would already be done.

What an outstanding idea - VTEC power and RWD all at once! It should be an awesome car. It's definitely wise to discuss your project at an early stage with a category 1D LVV Certifier. Your LVV Certifier will identify things you'll need to do to help you get through the LVV certification process at the end of the build to minimise any possible hassles or re-work, and let you know when progress inspections will be needed. Have a look at the NZCCM - there's a bunch of good information in there about your kind of conversion.

Gearbox change from auto to manual – does it need a cert? I have got other mods planned as funds permit including coil-over suspension and a roll cage, but those things won't be happening until next year sometime. I don't want to get busted by the cops, because on my rego it says the car is an auto.

In most cases it will need LVV certification because of the changes needed to complete the conversion. One area that many forget is the brakes; the braking system must not be modified or changed (including the brake pedal). The full requirements can be found in the VIRM In-service certification (Miscellaneous items Engine and transmission), Section 13.1.

I recently fitted an aftermarket limited-slip differential. This diff is tight, and as such makes a few bangs and tyre squeals at low speed. Are there any laws in place for this type of modification?

You've got a limited-slip diff which is completely legal. A locked diff (welded gears or spool) isn't legal. A super-tight limited slip diff (LSD) (which some are notorious for) can cause the same kind of low-speed tight-radius 'grabbing' that a spool or locked diff will. Adding friction modifier to your diff oil may relieve the binding action.

Exhaust Gas Emissions

Back to page index | Back to top of page

Do I need to fit a catalytic converter to a VS Commodore with an LS conversion?

It depends on a number of things, principally when the vehicle was manufactured, the first date of registration in New Zealand, and when the engine was first available. The VS was manufactured between 1995 and 1997, and the LS1 was first seen in a Holden from 1999 in the VT Series 2 Commodore. In this case, the vehicle would not need a catalytic converter, however, each situation needs to be considered on its own merits.

The flowchart below is taken from the LVV Standard 90-10(03) (Exhaust Gas Emissions) and can be used as a guide when deciding if your vehicle needs a catalytic converter fitted.

Click to enlarge

Exhaust Noise Emissions

Back to page index | Back to top of page

My car has been green stickered for being too loud, what do I do?

You’ll need to contact an LVV Certifier with ‘EX’ category, who will carry out an Objective Noise Test (ONT) on your car. The same process applies for motorcycles. You can find a list of LVV Certifiers here.

What happens once my car passes the noise test?

Your car will be fitted with an Electronic Data Plate, which will show measurements of the exhaust system and photos of the exhaust system taken by the LVV Certifier. The changes to the ONT system and introduction of EDPs are explained in this information sheet.

What is the maximum noise level allowed for exhausts?

This depends on the vehicle - refer to 'Decibel level requirements' on Page 17 (section 11.21) of Chapter 11 - Emission Systems Part 1 (Exhaust Noise) of the NZ Car Construction Manual.

Who can carry out Noise Testing?

Many WoF garages and exhaust shops can do a quick noise check to give a rough noise level guide, but only an LVV Certifier can do an Objective Noise Test, which is required to pass a vehicle that has been green-stickered for noise. You can find a list of Exhaust Noise approved LVV Certifiers here.

I have a stainless muffler on the rear of my car with a removable baffle in it to keep the noise down. The piece bolts in and out in a couple of minutes, which is cool because I leave it in for the street, and then pull it out when I've been racing at the night drags. I went for a WoF at the Testing Station and was failed because the baffle is easily removable. The inspector told me I had to have it welded in place or to change the rear muffler completely. Is that right?

This is a grey area, and up to the interpretation of the WoF inspector. WoF rules require a muffler to be constructed or adapted in such a way that its operation or effectiveness cannot be readily interfered with - you might never have heard of this one before, but it's actually been in the regulations since at least 1976. A simple adjustment of a tuning device, or removal of the innards of a muffler from the rear of the vehicle without tools clearly constitutes a system that can be readily interfered with so is not allowed. If tools are required, then it is less readily tampered with, but an inspector could still fail it and you would have to weld it up or replace it. If the exhaust is being noise tested by an LVV Certifier and won’t pass without the baffle, they are more likely to require that it is welded in place before passing it.

Exhaust exit pipes - can I run one out the side of my front bumper? Same for my wastegate, I want to vent it out next to the exhaust.

No. Exhaust gases must be directed away from the perimeter of the vehicle's passenger compartment. The intention behind the rule is to prevent exhaust gases coming inside the passenger compartment and sending you to sleep through carbon monoxide poisoning. Exiting the exhaust gases at the front of your car will enable them to come back over, under, and around the car while you are driving, and enter the passenger compartment through the ventilation system, side windows, or any small gaps. Exhaust gases need to exit toward the rear, behind the rear-most passengers' seating position(s). Provided the latter is achieved, they can dump out the side or under the car if this is how the OE manufacturer routed the exhaust.

Externally venting wastegates (screamer pipes) are not permitted and cannot be LVV certified as they are not adequately muffled and the exhaust gasses do not exit behind the passenger compartment. However, wastegates that feed gasses into their own muffled exhaust system exiting behind the passenger compartment, or feed gasses back into the vehicle’s exhaust system, are permitted.

Exhaust flame thrower kits and electronic cutouts - legal or not?

They are not legal. The VIRM In-service certification (Exhaust/Exhaust system), Section 11-1, Reasons for rejection, paragraph 4 states:

“The exhaust system is so constructed or modified that its operation or effectiveness can be readily interfered with, eg the driver is able to interfere with the exhaust system by operating a manual switch, or the exhaust is fitted with a flame thrower kit.”

A ‘Bi-modal’ system may be fitted if it does not have a driver-operated switch, something like the system fitted to a high-volume manufactured vehicle (HSV/Audi etc) would be ok but it cannot exceed the applicable noise limits in either mode.

FRONTAL IMPACT

Back to page index | Back to top of page

I want to replace my SRS airbag steering wheel with a sports steering wheel. Does it need to be certified?

Yes, but there are conditions that need to be met, and you might need to make other changes before the cert can be completed. The full details can be found in the LVV Standard 155-30(02) (Frontal Impact), but the most common issues are as follows:

-

The car needs to be at least 14 years old; and

-

only the affected airbag should be removed; and

-

the remaining systems (i.e. passenger airbag) need to remain active; and

-

you’ll need new replacement seatbelts in affected seating positions; and

-

you’ll need to display a label (which your LVV Certifier will provide) to warn anyone using that seating position that there is no airbag fitted.

Note that a vehicle with an LVVTA-approved Authority Card that specifies ‘Removal of a manufacturer-installed occupant protection system’ does not require LVV certification for SRS Air Bag removal.

Why does a seatbelt have to be replaced if the SRS airbag has been removed?

LVVTA requirements specify that the seatbelt must be replaced when airbags are removed. This is to ensure that an occupant no longer protected by an airbag has the best possible level of safety in the event of a collision.

- The seatbelt is generally designed to work in conjunction with the SRS airbag as part of an integrated safety system and may not perform as intended without the airbag.

- The webbing can degrade over time from UV exposure, contamination, and general wear and tear.

- The seatbelt will usually incorporate a pre-tensioner, which is part of the SRS and this is not intended to operate without an air bag.

- As airbags can't be replaced unless the vehicle is 14 years old, the seatbelt is likely to have some wear within its mechanical components.

- Replacing the seatbelt ensures the occupant has the best possible level of safety and protection in the event of a collision.

-

Fuel Systems

NZ Car Construction Manual - Chapter 10 - Fuel Systems

Back to page index | Back to top of page

Do I need a cert if I replace my fuel injection system with a carburettor?

Yes, changing fuel delivery systems from either fuel injection to carburettor or from carburettor to fuel injection will require LVV certification.

Can I put carpet in the boot under my fuel cell?

No. NZCCM Chapter 10 (Fuel Systems), Clause 10.6.1 requires that in the case of a fuel tank rupture, fuel must be able to drain away effectively. Putting carpet in the boot would not allow this.

Can I replace my mechanical fuel pump with an electric pump without certification?

You can, provided the electric fuel pump:

-

is a replacement for a mechanical pump on a carburettor engine; and

-

is adequately supported; and

-

does not increase the fuel pressure above OE

-

GLAZING & VISION

Back to page index | Back to top of page

Can plastic glazing be used instead of the OE glazing?

Yes, alternative glazing can be installed but it must be of a specific type – some abrasion resistant acrylics and polycarbonates are ok. The changed glazing must be LVV certified or specifically mentioned on an MSNZ/NZDRA authority card. The front windscreen material, however, cannot be changed. Refer to the NZCCM Chapter 15 (Glazing & Vision).

Can I fit mirror style tinted windows on my car?

The VIRM, In-service certification, General vehicles (Vision/Glazing), Section 5.1.6, Tables and images, Permitted modifications, Overlays, states that glazing must not:

“have a mirrored effect that is sufficient to dazzle other users”

Therefore, this would preclude most mirror tints. Also, the windscreen visible light transmittance (VLT) must be at least 70% and the VLT of side windows and rear windows of cars and station wagons must be at least 35%.

Some WoF inspectors have a device that shines light through a window to test the VLT, while others have a sample of compliant tint that they can use to compare.

How can I achieve a good wiper swept area on a custom or modified wiper system?

This can be tricky to do in some cases, but especially with low or vertial windscreens. There's some good tech on this subject available online, and this one on YouTube is a good place to start.

INTERIOR

Back to page index | Back to top of page

I want to replace my SRS airbag steering wheel with a sports steering wheel. Does it need to be certified?

Yes, but there are conditions that need to be met, and you might need to make other changes before the cert can be completed. The full details can be found in the Low Volume Vehicle Standard 155-30(02) (Frontal Impact), but the most common issues are as follows:

-

The car needs to be at least 14 years old; and

-

only the affected air bag should be removed; and

-

the remaining systems (i.e. passenger air bag) need to remain active; and

-

you’ll need new replacement seatbelts in affected seating positions; and

-

you’ll also need to display a label (which your LVV Certifier will provide) to warn anyone using that seating position that there is no air bag fitted

Note that a vehicle with an LVVTA-approved Authority Card that specifies ‘Removal of a manufacturer-installed occupant protection system’ does not require LVV Certification for SRS Air Bag removal.

Can I strip out my interior? I want to pull all the carpet out as well as the rear seats and all the plastic trim in the back and the boot. All I'll have left is the two front seats and seatbelts, the dash and centre console etc. Will this pass a WoF?

Yes, but you will need to ensure that the interior surfaces continue to meet the requirements found in the VIRM In-service certification, General vehicles (Vehicle interior/Interior impact), Section 7-7, which states:

“Interior fittings, controls and surfaces in the passenger compartments must be such that the likelihood of injury to occupants is minimised.”

Removing any/all of the seats except the driver's seat is ok as an under-threshold modification, however, in some situations (like a van) a class change and a new load rating may be required.

What’s the difference between a roll-cage and a roll bar? What can I have in my car?

A roll-cage is a full structure that extends forward of the front seats and will usually run along the roofline, across the top of the windscreen, and down both the A and B pillars. It will often include bracing and side intrusion bars. A roll bar does not extend forward of the front seats except for lower side bars and usually runs up next to the B pillar and across the roofline behind the front seats and is braced rearward. In any case, no part of a roll bar or roll cage can be within the vehicle occupant’s A-zone (the area where your head would be).

Roll Bar: In some cases, a roll bar can be installed without the need for LVV certification, but if you don’t meet the criteria, LVV certification is required. To have a roll bar LVV certified in a Class MA vehicle (passenger car) that is positioned in the B-zone, there are a couple of ways to do it. The first is where part of the roll bar is in the B-zone, in this case, you will need to meet certain requirements such as having a head restraint fitted, padding in appropriate places and ensuring there are no sharp edges. Alternatively, you can have the roll bar positioned in the C-zone, in this instance it is far enough away from you and any passengers as to not be a hazard and it will just need to minimise the likelihood of injury. For full information and definitions of the occupant cell zones please refer to the LVV Standard 155-40 (Interior Impact).

Roll Cage: In most cases to have a full roll-cage in a Class MA vehicle (passenger car) you will need to have a valid LVVTA-approved authority card. Contact MotorSport NZ for suitable roll-cage design and construction requirements and for LVVTA Authority Card conditions.

If your vehicle has back seats and you would like to keep them, you will need to ensure no part of the roll bar is in the A-zone (for the backseat occupants) and any roll bar in the B-zone meets the requirements in LVV Standard 155-40 (Interior Impact).

Note that in almost all cases, you won’t be able to retain the rear seat due to the added bars, which introduce an interior impact head-strike issue.

LIGHTING

NZ car Construction Manual - Chapter 17 - Lighting Equipment

Back to page index | Back to top of page

Are High-Intensity Discharge (HID) or LED headlights legal to fit?

Yes, if you are replacing the entire lamp and not just the bulb(s). A headlamp must not be retrofitted with a type of light source other than that specified by the vehicle manufacturer or the headlamp manufacturer (e.g. a headlamp designed for a halogen bulb cannot be fitted with any other type of light source such as an HID or LED bulb, or any other light source such as LED strips or non-OEM ‘angel eyes’). It is permitted to replace a complete halogen headlamp unit with a complete HID or LED headlamp unit.

Note: If the vehicle is required to meet an approved safety standard for headlamps, only approved headlamps can be retrofitted. In most cases swapping headlamps won’t require LVV certification but may be more difficult in more modern vehicles.

Can I fit clear-style taillights for my Honda? The trouble is I've heard conflicting stories from my mates about how legal (or illegal) they are. The lights have red and orange bulbs with them, but other than that they are completely clear.

If the vehicle is going through Entry Compliance, any replacement taillights, clear or standard, must meet one of the NZTA approved standards . Before you buy, check that they have one of the standards marked on the outer plastic lens. If not, ask the supplier to prove to you through documented evidence showing they do in fact comply with an approved standard, and keep a copy of it.

Approved standards are UN/ECE 7, 76/758/EEC, FMVSS 108, ADR 49, JIS D 5500 or any Japanese Technical Standard. However, if the vehicle is already registered, the requirements are more relaxed, and you can change them as long as they meet the VIRM, In-service certification, General vehicles (Lighting), Section 4, requirements for condition and performance.

-

What rules are there for modifying a motorcycle or trike, and where do I find them?

LVVTA is in the process of developing a motorcycle standard, with trikes to follow. In the meantime, you can use the LVV Formset #FS015 Trikes with Motorcycle Controls as a guide and work closely with your LVV Certifier.

A Motorbike that was originally sold for off-road use (i.e. a farm bike or dirt bike) and so does not comply with on-road regulations and is not in the system. Can it be brought up to legal requirements and be put on the road?

Not usually. The standard bike would need to show compliance to all applicable NZTA Entry requirements before an LVV Certifier considers any modifications and this can't usually be done. However, some bike manufacturers do sell on-road kits to legally convert their trail bikes. You cannot circumnavigate this by LVV certifying it as a scratch-built as it is a mass-produced bike.

SEATS & SEATbelts

Back to page index | Back to top of page

I’ve found some aftermarket seat rails online that are specifically to mount a Recaro seat to my type of car. As they’re not welded and don’t require any mods to the car itself, can I use them without a cert?

We’ve seen a few of these now and while they all sound good, sadly we’ve also seen many that don’t comply with WoF requirements without LVV certification. This is most commonly due to the seatbelt mount, which was part of the OEM seat rail, now becoming part of the new aftermarket rail. Any change in seatbelt mounts, even those that place the fastener back into the same position require LVV certification. If the belts were originally mounted to the floor pan of the vehicle, not the seat itself, then yes, you may not need a cert.

-

I want to put a bench seat into my vehicle but it’s too wide, can I cut a section out and weld it back together to make it smaller?

Yes, you can cut and weld the seat, provided it doesn’t prohibit the seat from meeting all relevant requirements. You will need to ensure the original strength and rigidity of the seat structure is retained and the seat still meets the minimum size (width) for a bench seat in a low volume vehicle - 410mm wide per seating position for adults, 310mm for children.

I have a Prelude and am considering removing the back seat and putting my subwoofers there instead, would I need a cert for this?

LVV certification is not required where the only modification is the removal of seats and/or seatbelts. You should remove every part of all seatbelts, or it may cause issues at WoF time. If it’s a permanent change you should get the details altered in NZTA’s records by taking the car to a testing station (VTNZ, VINZ or AA) to get it recorded as a 2-seater. Your insurance company may also want to know (they usually want details of any modifications). The addition of the speakers doesn’t require LVV certification either, as long as you aren’t cutting out any structural material. The box should be secured well enough to withstand 20 times its own weight in terms of a frontal impact. Using the old rear seatbelt mounts is a good idea, perhaps with a steel strap over the box.

Can a vehicle seat be raised for a short person if there is an airbag in the steering wheel?

Yes, within limits. A 50mm raise is usually ok as it would put the person’s head into a position closer to that of an average person, which is better for effective airbag operation. LVV certification would be required.

Does my vehicle need to have headrests fitted to it?

LVVTA strongly recommends the use of headrests (head restraints). Head restraints are not mandatory for all vehicles but are required in certain circumstances, such as a scratch-built vehicle seat fitted with harness seatbelts and a seating position with a roll bar immediately behind.

A front head restraint must not be removed if the vehicle is required to comply with a frontal impact occupant protection standard, and a front or rear head restraint must not be removed if there is a solid structure within 300mm of the seatback.

If it is difficult to fit a head restraint to a seat, it can be attached to the vehicle structure, such as the back of the cab, either from below the rear window or on a horizontal bar spanning across the window.

The requirement for head restraint fitment can be found in the NZCCM Chapter 14 (Seats, Seatbelts & Anchorages), section 14.10. Design and construction requirements for head restraint are in the Low Volume Vehicle Standard 185-40(02) (Head Restraints).

The VIRM, In-service certification, General Vehicles, (Vehicle interior/Head restraints), Section 7.3, Tables and images requires that a front head restraint must not be removed from a vehicle required to comply with a frontal impact occupant protection standard (e.g. cars built from 1999). Neither front or rear head restraints may be removed if there is a solid structure within 300mm behind the seatback.

Can seats and seatbelts from one car be put into another car?

This can be done without LVV certification only if the seats and seatbelts meet the VIRM, In-service certification, General Vehicles, (Vehicle interior/Seats and seat anchorages), Section 7.1, Tables and images, all replacements mount to existing OE mounts without any modification, they meet applicable WoF condition and performance requirements; are of the same type, and have standards labels that prove the belts comply. Seats that require LVV certification must meet the LVV standards for seats seatbelts, headrests (head restraints) and interior impact. Other items to bear in mind are frontal impact protection components that may be directly or indirectly affected, such as pre-tensioner seatbelts and seat side airbags.

Do seats fitted in older vans need to be certified?

Seats fitted pre-1 March 1999 to a van with more than 9 seats do not require LVV certification provided the vehicle has been continuously registered. Seatbelts do not have this cut-off date so if fitted, would require LVV certification regardless of the date.

Seats fitted between 1 March 1999 and 1 October 2004 are subject to LVV Info-sheet #05-99 (Frame and Mounting Strength for Additional Seats). LVV Standard 185-00 (Seats and Seat Anchorages) applies to all seats fitted after 1 October 2004.

I want to replace my SRS airbag seats. Can I legally do this, and does this need to be certified?

Yes you can and yes it does, but there are conditions that need to be met, and you might need to make other changes before the cert can be completed. The full details can be found in the LVV Standard 155-30(02) (Frontal Impact), and LVV Info-sheet #01-2020 (Removal of Front Seats Fitted with Side Airbags but the most common issues are as follows:

The car needs to be at least 14 years old, only the affected airbag should be removed, the remaining systems (i.e. passenger airbags) need to remain active, you’ll need new replacement seatbelts in affected seating positions, and you’ll need to display a label (which your LVV Certifier will provide) to warn anyone using that seating position that there is no airbag fitted.

Note that a vehicle with an LVVTA-approved Authority Card that specifies ‘Removal of a manufacturer-installed occupant protection system’ does not require LVV Certification for SRS Air Bag removal.

Why does a seatbelt have to be replaced if the SRS airbag has been removed?

LVVTA requirements specify that the seatbelt must be replaced when airbags are removed. This is to ensure that an occupant no longer protected by an airbag has the best possible level of safety in the event of a collision.

- The seatbelt is generally designed to work in conjunction with the SRS airbag as part of an integrated safety system and may not perform as intended without the airbag.

- The webbing can degrade over time from UV exposure, contamination, and general wear and tear.

- The seatbelt will usually incorporate a pre-tensioner, which is part of the SRS and this is not intended to operate without an air bag.

- As airbags can't be replaced unless the vehicle is 14 years old, the seatbelt is likely to have some wear within its mechanical components.

- Replacing the seatbelt ensures the occupant has the best possible level of safety and protection in the event of a collision.

Is it legal to fit a full harness seatbelt in my car?

For a production road car, the only way to have a full-harness belt is with a MotorSport NZ or NZ Drag Racing Association authority card. Harnesses are also allowed in scratch-built vehicles like scratch-built sports cars, and kit cars, but only if they have a single-row of seats and only where they meet other specific requirements. Refer to Section 14.32 of NZCCM Chapter 14: Seats, Seatbelts and Anchorages for further information.

Can I fit my Lancer GSR RS with a pair of Recaro seats out of an Evo? The seats are the FIA-approved SPG model and were fitted to Recaro rails which have bolted directly into my GSR.

It will depend on the original seat, if it was a stressed seat (seatbelt attached to seat, rail, or seat frame) then it will always require LVV certification as it is a modification that affects a seatbelt anchorage.

You can avoid LVV certification if the OE seat meets the threshold requirements in the VIRM In-service certification (Vehicle Interior/Seats and seat anchorages), Section 7.1, Tables and images, including that the seat is unstressed and is either an unmodified OE seat from another vehicle or of a known and reputable aftermarket brand.

I want to put swivelling front seat bases in my campervan. They just bolt in, do they need certification?

An aftermarket swivelling seat base is an above-threshold modification and must be LVV certified. Quite often, this will involve moving a seatbelt anchorage as part of the fitment of the swivel seat base. A swivelling seat base must have appropriate testing documentation that can be supplied to the LVV Certifier to prove that it is fitted to the correct model of vehicle and can withstand the forces imposed on it in a crash. Quite a few van seats are “stressed” (i.e. there is a seatbelt anchorage attached to the seat frame), which means that the swivelling seat base must meet very specific loading requirements.

Steering

Back to page index | Back to top of page

I want to replace my SRS airbag steering wheel with a sports steering wheel. Does it need to be certified?

Yes, but some conditions need to be met, and you might need to make other changes before the cert can be completed. The full details can be found in the LVV Standard 155-30(02) (Frontal Impact), but the most common issues are as follows: The car needs to be at least 14 years old; only the affected airbag should be removed; the remaining systems (i.e. passenger airbag) need to remain active, you’ll need new replacement seatbelts in affected seating positions; and you’ll also need to display a label (which your LVV Certifier will provide) to warn anyone using that seating position that there is no airbag fitted.

Note that a vehicle with an LVVTA-approved Authority Card specifying: “Removal of a manufacturer-installed occupant protection system” does not require LVV Certification for SRS airbag removal.

Can I fit a quick-release steering wheel adaptor to my vehicle?

Quick-release steering wheels are not recommended for road use and should only be fitted where the design of the vehicle makes the installation of a quick-release steering wheel necessary for easing entry and exit. In practice, this means a quick-release steering wheel is limited to use in motorsport vehicles with a roll cage, small kit cars like the Lotus 7 replica, or where there is reasonable justification such as specific mobility issues. Enabling quick removal of a steering wheel as a security measure, is not considered sufficient justification for the additional risk that a quick-release mechanism introduces into the steering system, and in a similar vein, a tall driver in a vehicle with an otherwise unmodified interior, would be unlikely to be considered sufficient justification. LVV Certification is always required for the addition of a quick-release steering wheel adaptor.

Note 1: Where an LVV Certifier has confirmed that a vehicle can legitimately be fitted with a quick-release adaptor, the technical requirements contained in section 7.5, Quick-release steering wheels, of the Steering Systems chapter of the NZ Car Construction Manual must be met.

Note 2: Some quick-release steering wheel adaptors are designed to be welded to the top of the steering shaft. This type must be avoided - welding of steering shaft is not permitted, and cannot be LVV certified.

Note 3: There are numerous poor quality, dangerous and non-compliant bosses available. See Safety Alert.

Note 4: Some aftermarket quick-release adaptors use a push-button, and require the locking ring to be twisted into place to lock/unlock the steering wheel. This style does not self-lock and cannot be LVV certified.

Can a vehicle be certified that is constantly sitting on the bump stops?

No - All low volume vehicles must be fitted with purpose-designed bump-stops that are positioned to provide sufficient clearance from any suspension components so as to allow suspension travel suitable for the safe operation of the vehicle when fully laden.

Suspension

NZ Car Construction Manual - Chapter 6 - Suspension Systems

Back to page index | Back to top of page

Can my car be certified with suspension measuring under 100mm ground clearance?

The 100mm suspension height limit (measured from the underside of the vehicle to the road surface) is a ‘modification threshold’. The modification threshold is a method of determining how far a vehicle can be modified without requiring LVV Certification. Click here to view the WoF VIRM, and then click on the ‘Tables and images’ tab to view the suspension threshold.

The 100mm suspension height threshold should only be applied to a vehicle which has not had its suspension system LVV Certified. The only way to determine whether the suspension system has been LVV certified for lowered or modified suspension, is to check the details which have been recorded on the LVV certification plate - new suspension heights will be recorded in the ‘Susp/axle’ field.

A vehicle can be LVV certified with a suspension height of less than 100mm; as part of the certification process the LVV Certifier will ensure (amongst other items, refer to the LVV Suspension Standard) that the vehicle has adequate suspension travel and clearance to bump stops, and that the suspension performs correctly. The LVV Certifier will make the decision as to the appropriate suspension heights, which will be recorded on the certification plate.

The measurement recorded on the LVV certification plate should be checked or measured with the vehicle parked on a flat surface in an unladen state (no occupants or cargo), and should be measured from the centre of the wheel rim upwards to the top of the wheel arch. These suspension heights have a 5% tolerance to allow for spring sag or other minor inconsistencies.

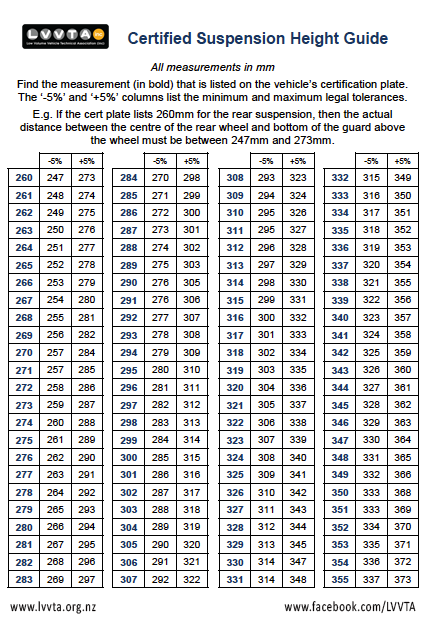

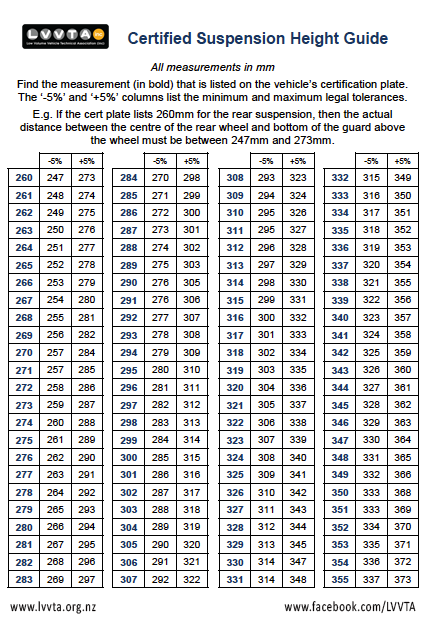

How do I work out the 5% height tollerence?

Here is a quick-reference table that gives you the 5% tollerence on suspension heights between 260mm and 355mm.

I’m looking at raising my 4WD, how high can I go? Is there any limit?

This is a very tricky question to answer simply because there are so many modification possibilities, all of which may have a different impact on how the vehicle rides or handles. Essentially there is no set maximum figure, but your LVV Certifier will inspect the vehicle (and fitted components) and assess the vehicle as a whole. Lifting a thirty-year-old 4WD with a live axle is very different to lifting one with independent suspension, so the LVV Certifier will look at a large number of things including (but not limited to) the type of suspension you have and whether the geometry has been affected, how the suspension was raised, ball joint spacers or other parts that may have been fitted, the steering, the tyres, and the body lift if fitted.

There are potential complications for late-model vehicles that have advanced driver assistance systems (ADAS), such as stability control and autonomous emergency braking. These systems rely on accurate positioning of sensors which could be affected by even a small suspension lift.